Titanium Motor Arts

Product Design & 3D ModelingMain Page

Industry Type: Manufacturing

Location: Princetone, NJ

Company Size: Micro Cap

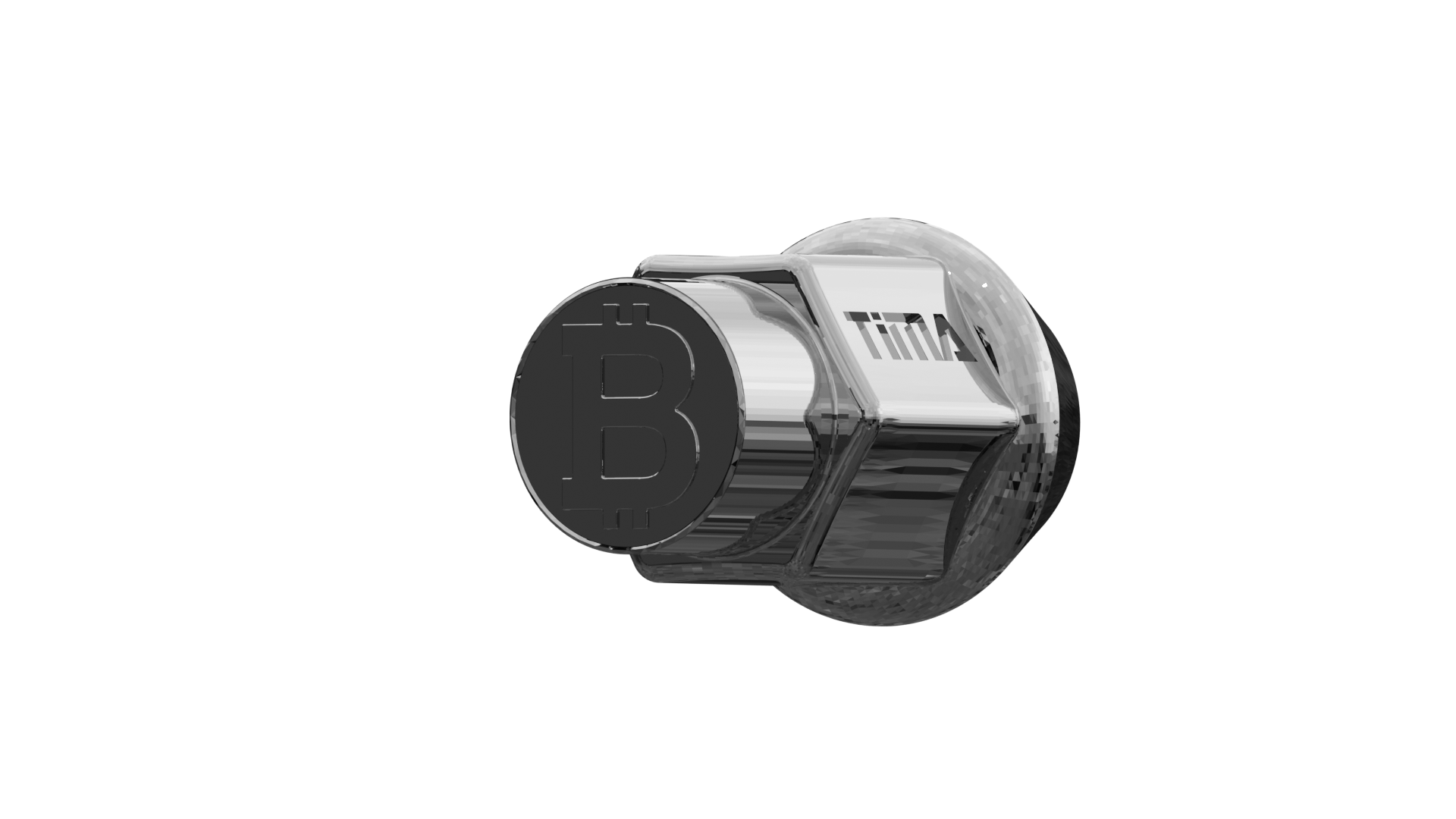

Product: Titanium Lug Nuts

TiMA’s product line is focused on museum-quality customized luxury car accessories – coupling the functionality and durability of Titanium with high-concept sculptural designs.

Style & 3D Renderings

#e02b20

#1F2021

#444444

#afafaf

#FFFFFF

Aa

Aldrich Semibold 32pt

Average Sans 24pt

Average Sans 16pt

Average sans Bold 14pt

TiMA produces the ultimate in customized titanium accessories for luxury car owners worldwide employing proprietary Titanium fabrication and surface coating technologies

TiMA’s product line is focused on museum-quality customized luxury car accessories – initially lug nuts – coupling the functionality and durability of Titanium with high-concept sculptural designs that individualize an owner’s car

Deliverables

- 3D Product Renderings

- 3D Printing Specs

- Landing Page

Services

- Product Design

- Visual Identity

- Investor Landing Page

Strategy

- Go-to-market strategy

- SEO

Project Info

2022

Challenge

We worked with the founders of TiMA to introduce the first-ever 100% titanium, 3D-printed lug nuts for the luxury buyer to the supercar category.

Creating a unified experience for investor’s questions to be answered on one page.

Solution

To bring the company’s radical new idea to market, we developed a brand inspired by its pure ingredients of titanium, water, and sun and collaborated with Alessio Monti on product design and 3D modeling.

Investors have information about TiMA’s product and market opportunity.

Titanium Motor Arts — Wheel Art Forged in Titanium

Brand Strategy

A best-in-class personalized lugnut B2C experience

Working on showcasing the first-ever 100% titanium, 3-D printed lug nuts, QWARTER designed the product options and investor material flow that supports multiple product formats. This allowed TiMA to simplify the value proposition and underlying magic behind this new invention. New checkout selections make it easy for customers to choose their size, jacket style, animal, and style of painting.

Impact

Purpose

TiMA’s patented and proprietary technology imitates conventional manufacturing by using 3D printing TiMA to decrease carbon footprint in the manufacturing space.

Decrease Carbon Footprint

Vision

With carbon dioxide (CO2) levels at the highest they’ve been in 23 million years, manufacturing is currently the largest threat to climate change and humanity. With safe production and safe commercial use across a vast number of industries, titanium will bring major benefits to society, with no harmful effects on people or the environment.

“Almost” Impossible

Collaborators

Alessio Monti

- Product Design / Blender

- Specifications for 3D printable product manufacturing

3D Designer

Sergio Monti

- Logo Design

- Web Design

- Identity

Art Direction

Indigo Varela

- WordPress Build

- CRM Integration

- Password wall for Idea Protection

Developer

“Qwarter’s exceptional team helped bring TiMA’s vision into 3D printable products – giving us the edge of being the first 100% titanium car accessory manufactured through 3D printing. Qwarter successfully helped the TiMA team turn a product idea into a product and an attractive investment opportunity for players in the high-end luxury space. From ideation of product ideas to in-hand lug nuts made from a computer program, and other possible products, TiMA now has a way into a highly competitive landscape by being the first to market.

Next